Overview of the Development of Plastic Products

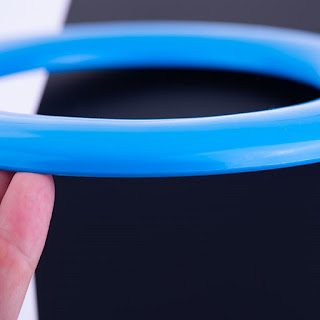

In this post, we go over the many sorts of analyses done while developing a plastic part to assure product quality. Injection moulding is the most widely used industrial technique for producing plastic items. With injection frisbee , a wide variety of things are produced, each with a distinct size, degree of complexity, and use. A mould, raw plastic material, and an injection moulding machine are required for the injection moulding process. The plastic is melted in the injection moulding machine, injected into the mould, cooled, and solidified to create the completed product. An examination of the mould flow should be done before the first prototype of a plastic injection moulding die is started. Mould flow analysis is not necessary for every application. Plastic engineers will offer suggestions for including mould flow analysis in the production budget based on the product geometry and tolerance specifications. What is a Mold Flow Analysis in Plastic Product Design? Mold flow analysis

.jpg)