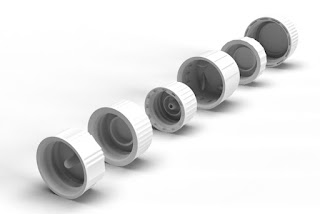

The best way to make a plastic injection mold

Moulding Injection is a specialist in the design and manufacture of plastic injection moulds. Their injection molds are manufactured with the best machinery and the most modern technology. This, combined with the use of high quality materials, guarantees the durability of the custom injection mould manufacturer . The specific heat treatments they use are adapted to the material with which the parts will be injected. This allows them to obtain a good quality of the parts and a longer useful life of the mold. They offer a complete service: design, manufacture and assembly of your injection molds. They offer single and multi-cavity injection molds, as well as the manufacture of other types of dies. They are familiar with the plastic injection mold design for sectors as diverse as the automotive, sanitary and industrial sectors. With each customer, they not only offer the best of their equipment, but they also ensure a complete follow-up of the manufacturing of the injection molding