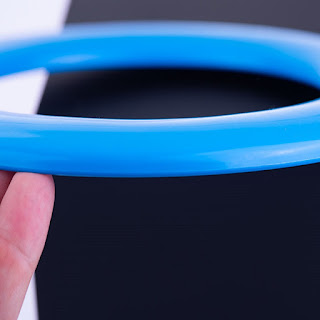

What Does Injection Molding's Parting Line Mean?

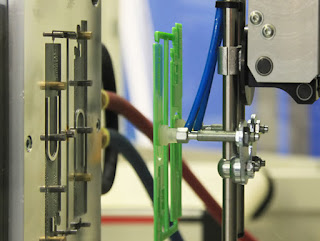

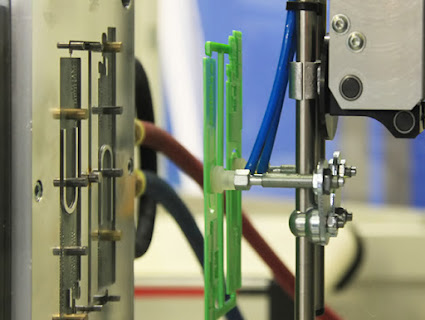

All injection frisbee components have a separation line that may be seen. When a mold's two parts are clamped together, a line separates them. Although molds must totally seal during the process, a faint visible line is always present on the finished product. The size and appearance of the line are determined by the plastic type and mold design. Parting Lines The term "parting line" describes a line on an Injection Molding component that is produced where the two halves of the mold converge. The end result is a thin, occasionally imperceptible line on the portion. This line often has little impact on the part's overall dimensions or shape, but it can be visually evident to varied degrees, depending on the mold finish, the type of material, the color of the material, and the processing conditions. There are a few strategies to reduce the visibility of this line on the molded item, but since injection molding uses a mold that has two sides, it is impossible to totally