Top 6 Things to Think About Before Getting an Injection Molding Quote

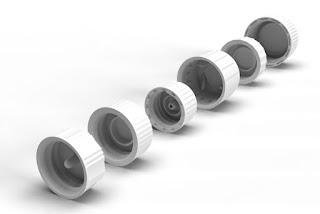

The most popular method for plastic molding is injection molding, which is used to make a wide range of intricate parts in various sizes and shapes. Whether producing a vinyl window part or a water bottle overcap, cheap injection molding is effective and affordable, especially when producing large quantities of parts. The largest portion of upfront production expenditures is spent on injection molds. Your injection molder ought to be able to give you a quote that details the prices for any custom injection molding project. The unpleasant process of soliciting estimates for each project falls to purchasing and procurement managers. The quotes can differ significantly depending on the input (in terms of drawings, prototypes, or sample parts). Molds that have more cavities, tighter tolerances, and a longer production life require longer to construct and cost more upfront. The best injection molding company offers long-term savings. These molds are easier to maintain and endure long