Factors to Consider in Plastic Injection Mold Design

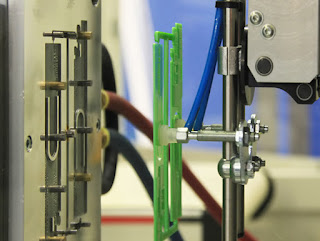

Plastic injection molding is a highly versatile and efficient manufacturing process used to produce a wide variety of plastic parts and products. However, the success of this process depends heavily on the design of the plastic injection mold. A well-designed mold can help to ensure the production of high-quality parts while reducing manufacturing costs and lead times. Plastic injection molding is a highly popular manufacturing process that is used to produce a wide variety of plastic parts and products. One of the key elements of the process is the design of the plastic injection mold. The mold design is critical in determining the quality and consistency of the final product. In this article, we will take a closer look at plastic injection mold design and its importance in the injection molding process. What is Plastic Injection Mold Design? Plastic injection mold design is the process of designing a mold that is used to create plastic parts through injection molding. The mold is